Our research is focused on the development of multifunctional sensors using advanced manufacturing technologies such as laser engraving, e-skin tattoos, and multilayered techniques. These sensors are designed to monitor a wide range of physical and physiological parameters, which can be used in digital healthcare, human-machine interfaces, and wearable electronics. By leveraging innovative materials and fabrication techniques, we aim to create sensors that are not only highly sensitive and durable but also comfortable and adaptable for long-term use. Our approach integrates strain, pressure, temperature, biopotential (ECG, EOG, EMG), and hydration sensors, which allow for continuous, real-time monitoring of various aspects of human health.

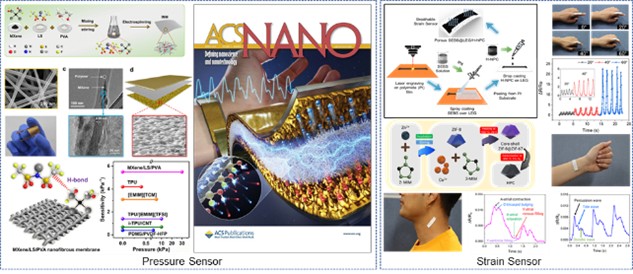

Pressure Sensors:

Pressure sensors detect mechanical forces such as touch, compression, and arterial pulse. In our lab, we focus on flexible capacitive pressure sensors, which offer high sensitivity across a wide linear range—critical for capturing subtle biomechanical signals in wearable systems. Recently, we have developed a sensor using a hybrid ionic nanofibrous membrane composed of Ti₃C₂Tₓ MXene and lithium sulfonamide salt embedded in a poly(vinyl alcohol) elastomer matrix. This design enables reversible ion pumping via hydrogen bonding, resulting in impressive sensitivities of 5.5 and 1.5 kPa⁻¹ across pressure ranges of 0–30 kPa and 30–250 kPa, respectively. With a rapid response time of 70.4 ms, a minimum detection limit of 2 Pa, and excellent durability over 20,000 cycles under 45 kPa, this sensor platform holds strong potential for next-generation mobile health monitoring and artificial electronic skin.

Strain Sensors:

Strain sensors play a vital role in wearable systems by capturing mechanical deformations linked to human motion, posture, and subtle physiological changes. Our lab is actively developing a range of flexible, stretchable strain sensors using diverse material systems and structural designs. These include both breathable substrates for long-term skin conformity and hybrid multifunctional sensors for advanced applications like e-skin. One of our key implementations uses porous MOF-derived carbon (HPC) on laser-engraved graphene (LEG), supported by a breathable PSEBS substrate. This configuration enables excellent stretchability and thermal comfort while achieving ultrahigh sensitivity (gauge factor ~575,542) and fine resolution (0.04%). Another platform integrates strain sensing with temperature functionality using a BP@LEG composite on SEBS, providing high performance in both domains with GF up to 2765 and long-term durability beyond 18,000 cycles. These examples illustrate our broader strategy of designing sensors that not only track motion and deformation with high fidelity but also withstand complex mechanical environments. We continue to investigate new nanomaterials, microstructuring techniques, and substrate innovations to further enhance performance and enable robust, skin-like sensor interfaces for healthcare, robotics, and HMI systems.

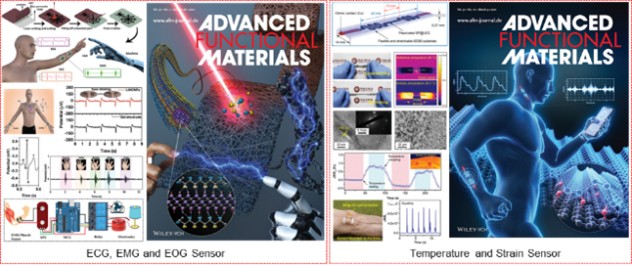

Biopotential Sensors (ECG, EOG, EMG):

Biopotential signals such as electrocardiography (ECG), electrooculography (EOG), and electromyography (EMG) are essential indicators of cardiac, ocular, and muscular activity, respectively. In our research group, we focus on developing soft, skin-conformal biopotential sensors that can reliably monitor these signals over long durations without compromising comfort or signal integrity. One of our notable advancements is the development of a breathable, reusable electronic tattoo made from laser-induced hierarchical carbon nanofibers (LIHCNFs) derived from MXene-reinforced PDFE nanofibers. This cost-effective approach delivers a high carbon yield (~54.77%), excellent conductivity (4 Ω/sq), and durability under repeated mechanical deformation. The resulting tattoo exhibits low electrode-skin impedance (~23.59 kΩ·cm²) and captures high signal-to-noise biopotentials (SNR = 41 dB), enabling accurate ECG, EOG, and EMG monitoring in wearable formats. The breathable structure (~14 mg/cm²·h water vapor transmission rate) ensures minimal skin irritation and promotes long-term usability, even during dynamic activities. Beyond this platform, our lab continues to explore new carbonization techniques, flexible electrode designs, and multi-modal integration to enhance the scope of human–machine interfaces, remote health diagnostics, and next-generation personalized electronics.

Temperature Sensor:

Temperature sensing is a critical component in wearable electronics for applications ranging from skin health monitoring to environmental perception. In our lab, we explore diverse temperature sensing platforms, investigating different substrates, functional materials, and structural patterns to achieve reliable and responsive temperature detection in wearable formats. One of our highlighted approaches involves a dual-functional strain–temperature sensor built on a SEBS substrate, using a hybrid material composed of black phosphorus and laser-engraved graphene (BP@LEG). This platform delivers a positive temperature coefficient behavior with a high thermal index of 8106 K (25–50 °C), enabling precise thermal mapping alongside high-performance strain detection. The modularity of our design strategies allows us to develop temperature sensors that are both application-specific and broadly adaptable, supporting integration into systems for e-skin, prosthetics, human–machine interfaces, and continuous health monitoring. As we continue expanding our portfolio, we are evaluating new composite materials, stretchable interconnects, and 3D sensor geometries to further improve accuracy, stability, and multi-parameter sensing capabilities.

Multifunctional Sensors

Our lab is developing cutting-edge multifunctional sensor systems that enhance human-machine interfaces (HMIs) and facilitate continuous digital healthcare monitoring. One of our notable innovations is the all-directional strain-insensitive stretchable electronic glove (e-glove). This e-glove integrates multimodal sensors capable of detecting pressure, temperature, humidity, and ECG with minimal crosstalk between the sensing modalities. Using a combination of CO2 laser engraving and electrospinning technology, the glove’s meandering sensing area maintains full stretchability while preserving sensor performance. The CNT-coated laser-engraved graphene (CNT/LEG) material used in the sensors maximizes sensitivity and minimizes stress effects, enabling precise detection of hot/cold, moisture, and even pain. Furthermore, the e-glove supports remote data transmission, offering potential applications in robotic skin, advanced prosthetics, and real-time healthcare monitoring. Alongside this, we have also developed a breathable, strain-insensitive multi-layered electronic skin (e-skin) for real-time monitoring of ECG, skin temperature, and hydration. This e-skin uses carbon nanotube and nanoporous carbon (CNT@NPC) ink, transferred onto porous SEBS substrates through a scalable benchtop process. The resulting hierarchical porous network facilitates multi-modal sensing without interference between different signals. With high breathability (3.49 mg cm⁻²·h⁻¹) and excellent strain insensitivity, this e-skin ensures accurate and continuous data transmission to a smartphone interface while monitoring vital signs such as ECG (26 ± 1 dB), temperature (0.198% °C⁻¹), and hydration (0.77% %⁻¹). This technology is poised for use in wearable health devices, enabling personalized, real-time health monitoring.